-

13

Dec

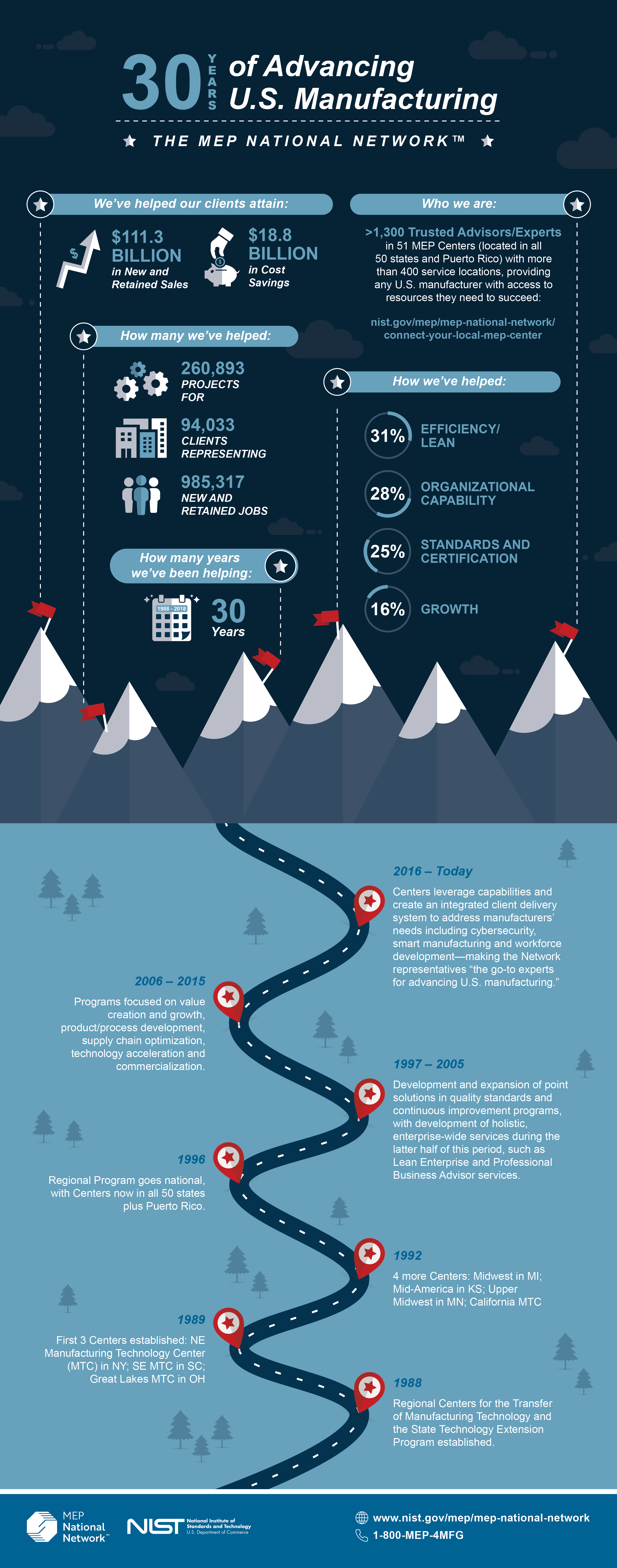

30 Years of Advancing U.S. Manufacturing: An MEP National Network Infographic

Written by Nico Thomas of NIST MEP

As you may have heard, the Manufacturing Extension Partnership (MEP) Program is commemorating its 30th anniversary this year. It’s got me thinking about that milestone in light of the MEP National Network’s mission to strengthen and empower U.S. manufacturers and its emphasis on delivering tangible economic impact. It begs the questions, “What has MEP accomplished in 30 years?” and “Is MEP delivering on its promise to strengthen and empower U.S. manufacturers?”

When you look at the cumulative impact data, the results are rather impressive. All told: Since 1988, MEP has worked with 94,033 manufacturers, leading to $111.3 billion in sales, $18.8 billion in cost savings, and it has helped create and retain 985,317 jobs.

Furthermore, these statistics are based on records that only date back to 1994, fully six years after the inauguration of the Regional Centers for the Transfer of Manufacturing Technology and the Assistance to State Technology Programs that would form the basis for a Manufacturing Extension Partnership. That means that only 80 percent of MEP’s history is represented by the cumulative impact numbers, giving them even more weight.

As you sift through the impact data rigorously recorded by MEP Centers, more impressive facts emerge. The MEP National Network engages with small and medium-sized manufacturers across the country, no matter what they specialize in. This sounds ambitious and idealistic, but the data shows that MEP’s efforts truly are all-encompassing.

In the last five years alone, MEP Centers have completed projects with manufacturers of every sub-sector of the manufacturing industry. That’s right, the MEP National Network has produced results for manufacturers that categorize themselves in every three-digit NAICS code in the manufacturing sector (31–33), including food and beverage, textile mills, woodworkers, chemical processors, plastic molders, foundries, boilermakers, machinery OEMs, and fabricators, among others.

One of the reasons MEP Centers may be so pervasive is that their service offerings reflect industry needs. MEP Centers have long focused on delivering point solutions that address immediate needs and deliver near-term impact. These include efficiency projects involving lean practices and sustainability and assistance in meeting industry standards and certifications (e.g., ISO, QS, AS).

During the twenty-first century, these MEP National Network services have also come to include longer-term organizational consulting (e.g., strategic planning, finance, workforce development) and growth projects (e.g., exporting, product development and technology commercialization).

Today, as manufacturing sectors get more specialized and as the general industry prepares for Manufacturing/Industry 4.0, the MEP National Network’s focus is on deepening expertise in areas such as cybersecurity, food safety, and advanced manufacturing technologies, including additive manufacturing, digital manufacturing, robotics, and smart manufacturing.

All in all, the data accumulated during MEP’s thirty years tells a compelling story about a mission-driven organization with ambitious goals fulfilling on its promise to strengthen and empower U.S. manufacturers, and in doing so, advancing U.S. manufacturing.